Auto-Filling Keurig Project

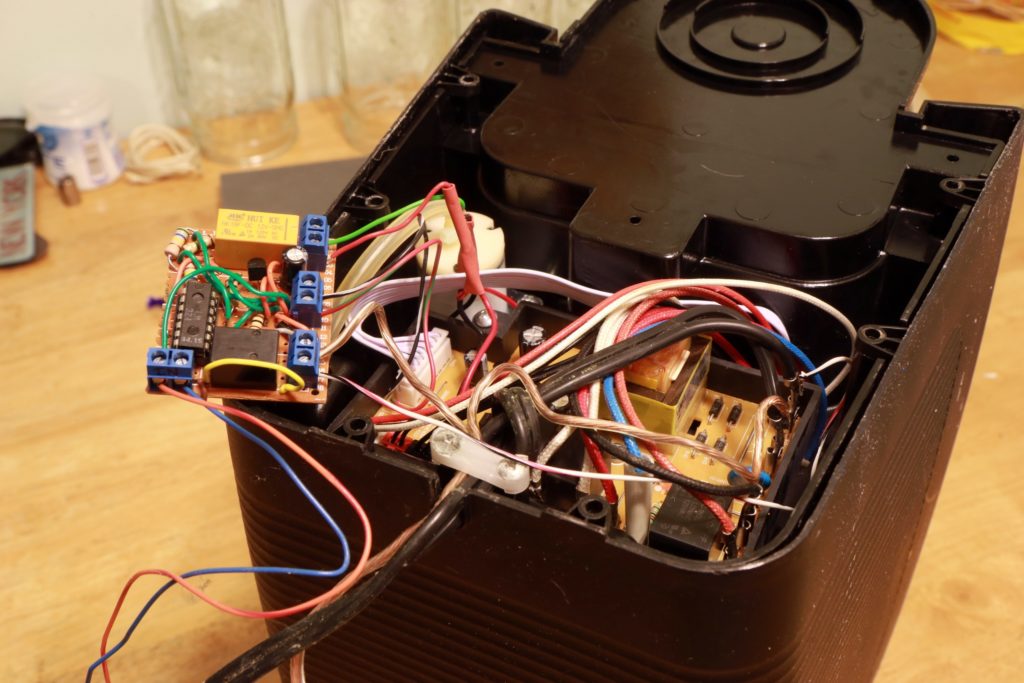

Analog circuit board for auto-refilling Keurig water reservoir.

After months of owning a small Keurig, I grew tired of having to fill up the reservoir every morning before making a cup of coffee. To solve this problem, I designed and built an analog DC circuit to sense water levels and fill when necessary.

The filler control circuit is powered off of 5vdc coming from the main board in the Keurig. When the pump motor in the Keurig kicks on to push the water out from the heating chamber and into your cup, the 5vdc is switched via a relay and fed to the filler control circuit and the high water level probe is active. If the water level is not in contact with the high water level probe, then the filler control circuit energizes a 120vac relay to turn the solenoid valve on allowing water to flow into the reservoir. Once the water level reaches the high water level probe, the filler control circuit de-energized the solenoid valve which shuts off the flow of water into the reservoir.

There were a few iterations I went through to get to this final circuit design. The first design continuously measured the water level and had a low level probe as well. This wasn’t desirable for two reasons. The water level probes began ionizing the water and minerals started to build up on them. Secondly, there was no fail safe in that design which meant that the circuit could inadvertently activate the solenoid valve and cause the reservoir to overflow. This could have created a huge mess and possibly water damage to surrounding objects. Through a few iterations, I was able to reduce the number of probes and introduce a fail safe by only powering the circuit during the short time that the pump motor is running. The end result is a filler control circuit that is safer, causes less buildup in the reservoir and is more efficient.

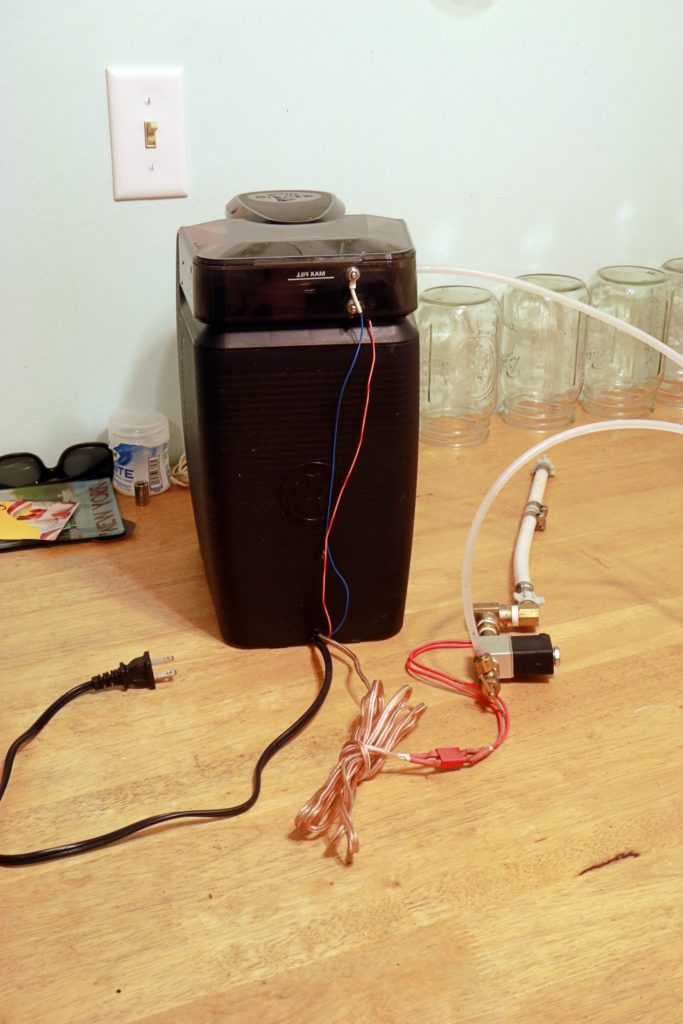

Automated Keurig Reservoir With Level Sensor

Keurig water reservoir with high water level sensor

Keurig Circuit v1

The first iteration of the automated Keurig circuit design.

Keurig Circuit v2

The second iteration of the automated Keurig circuit design. This design isolates the power going to the measuring part of the circuit to mitigate corrosion buildup on the sensor leads.

Keurig Circuit v3

The third and final design for the automated Keurig circuit design. This version eliminated the need for a low level sensor wire.